技術能力 Technologies

甚麼是MicroLED? What is MicroLED?

瑞利光智能將如何改變市場 How will RVI changes the market?

為甚麼MicroLED十分重要 Why MicroLED is important?

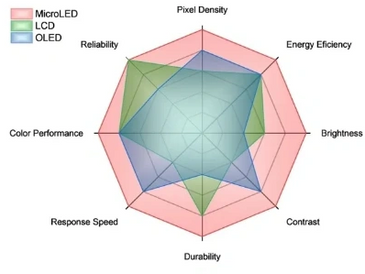

MicroLED通常被視為下一代發光技術。它使用小於50微米的LED作為獨立像素元件,可實現超高解析度、真RGB像素、高亮度、快速反應和高能源效率,性能超越所有傳統顯示技術。

MicroLED is generally interpreted as the next-generation light emitting technology. It utilizes <50 μm LED as individual pixel elements to achieve ultra-high resolution, true RGB pixels, high brightness, fast response, and power efficiency, which outperform every traditional display technology.

為甚麼MicroLED十分重要 Why MicroLED is important?

瑞利光智能將如何改變市場 How will RVI changes the market?

為甚麼MicroLED十分重要 Why MicroLED is important?

MicroLED卓越的性能實現真正沉浸式視覺體驗,突破傳統發光技術可能面臨的諸多限制,這使得MicroLED能整合於多種裝置中,包括AR/VR眼鏡、電視、智慧型手機、智慧手錶、抬頭顯示器(HUD)等。

MicroLED's superb performances enable truly immersive visuals, breaking through some of the obstacles traditional light-emitting technologies might face.

It enables integration of MicroLED in devices from AR/VR glasses, TV, smartphone, smartwatches, HUD, etc.

瑞利光智能將如何改變市場 How will RVI changes the market?

瑞利光智能將如何改變市場 How will RVI changes the market?

瑞利光智能將如何改變市場 How will RVI changes the market?

Raleigh Vision開創先進的3D MicroLED堆疊技術,實現超過10,000 PPI的解析度。我們的像素架構同時具備簡易維修的特性。

通過提升性能和製造可行性,尖端MicroLED技術得以合理良率和成本進入市場。

Raleigh Vision pioneers advanced 3D MicroLED stacking technology enabling over 10,000 PPI. Our pixel architecture also allows for easy pixel repair.

Through improving the performances and manufacturability, cutting-edge MicroLED

Raleigh Vision開創先進的3D MicroLED堆疊技術,實現超過10,000 PPI的解析度。我們的像素架構同時具備簡易維修的特性。

通過提升性能和製造可行性,尖端MicroLED技術得以合理良率和成本進入市場。

Raleigh Vision pioneers advanced 3D MicroLED stacking technology enabling over 10,000 PPI. Our pixel architecture also allows for easy pixel repair.

Through improving the performances and manufacturability, cutting-edge MicroLED can be released into the market with reasonable yields and costs.

核心技術 Core Technolgies

Smart+ MicroLED 智能製造技術 - Smart+ MicroLED Manufacturing Technology

我們專注於運用AI革新現有的MicroLED製造流程,包括巨量轉移、檢測和維修。我們相信運用AI演算法,包括機器深度學習、大型語言模型,能協助處理、預測並防範客戶最終MicroLED產品中的缺陷。

我們能依據客戶需求,靈活提供這些AI解決方案。

We focus on using AI to revolutionize current MicroLED manufacturing processes, including the mass transfer, inspection and repair. We believe the use AI algorithm, including machine deep learning, large language model, can help handle, predict, and prevent defects in our customers' final MicroLED products.

We can provide these AI solutions to our customers based on their needs with great flexibility.

XNOW MicroLED混Bin技術 - XNOW MicroLED Bin Mixing Technology

為克服顏色和亮度不均勻的問題,RVI致力於創新MicroLED製造流程。

透過XNOW混Bin技術,我們具備以下能力:

- 計算最佳均勻度的圖案

- 安排圖案和移動步驟以優化製造效率

- 在不同製程中實現分箱混合

To overcome the color and intensity non-uniformity, RVI has been striving on innovating the processes of MicroLED manufacturing.

With XNOW bin mixing technology, we have the ability to:

- Calculate the pattern with best uniformity

- Arrange the pattern and moving step for optimized manufacturing effort

- Achieve bin mixing in various processes

堆疊式MicroLED微型顯示技術 - Stacked MicroLED Microdisplay Technology

本公司的堆疊式全彩RGB技術具備多項優勢。它能在微型顯示器中實現超高8K解析度,而真RGB像素的MicroLED面板可提升影像銳利度和色彩表現。

平面結構適用於低像素密度的大型顯示器,但在高像素密度裝置上則面臨挑戰。由於RGB晶片需要在背板上分別佔據位置,這比堆疊結構多佔用約四倍面積,因此限制了最終像素密度。

堆疊結構的像素可製作得更小,因為R、G、B晶片大約只占用一個MicroLED晶片的面積。因此,本公司的設計相較傳統設計能實現更高效能、更佳性能的產品。

The Company’s stacked full-color RGB offers numerous benefits. It can achieve ultra-high 8K resolution in microdisplay, and true RGB pixels in the MicroLED panel enhance image sharpness and color performance.

Planar structure works well for large displays with low pixel density but struggles with high pixel density devices. Since RGB chips need separate positions on the backplane, this occupies about four times more area than stacked structures, thus limiting the ultimate pixel density.

Pixels with stacked structure can be fabricated smaller since R, G, and B chips occupy roughly the area of one MicroLED chip. As a result, the Company’s design enables more efficient and better-performing products compared to traditional designs.

堆疊式封裝式MicroLED (MiP) - Stacked-MicroLED-in-Package

基於堆疊技術打造全球最小的堆疊式封裝MicroLED產品,相較於傳統MicroLED晶片具備以下優勢:

- 提供各堆疊晶片的分箱分級數據

- 實現晶圓/面板級接合技術

- 全彩像素占用面積減少一半

- 整體晶片良率提升三倍

- RGB可同步轉移(轉移步驟減少至三分之一)

The world's smallest MicroLED-in-Package Product based on stacking technology.

Compared to conventional MicroLED chip:

- Provides bin-sorting data of each stacked chip

- Enables wafer/panel-level bonding

- Full-color pixel occupies 2x smaller area

- Offers 3x higher overall chip yield

- Allows RGB to be transferred simultaneously

(Reduced transfer steps by 3 times)